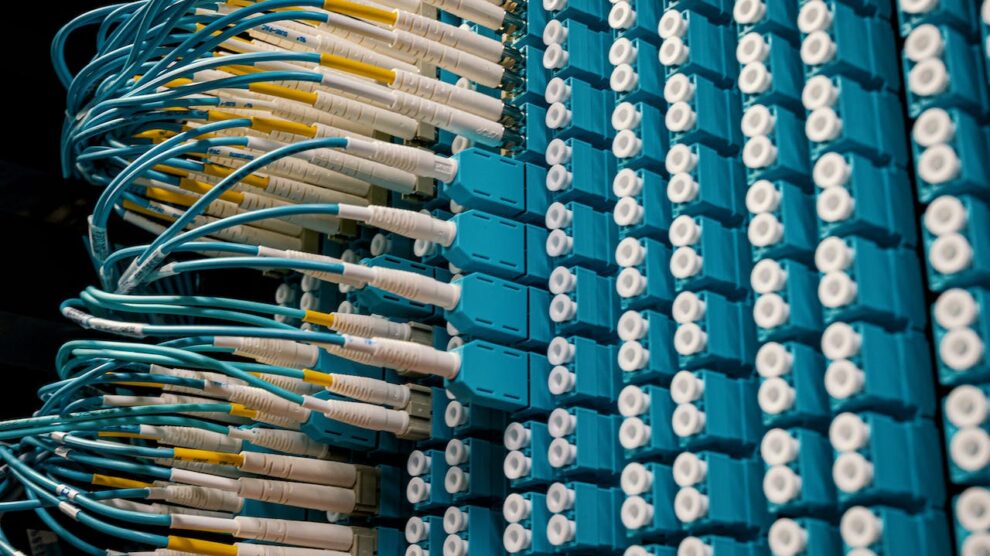

Fiber optic cables are delicate and costly. So, be sure to handle them with care. To ensure optimal efficiency and minimize the risk of damage, you need to employ proper handling techniques. Fiber optic cables often come with thin glass tubes that feature several layers of polymeric materials.

Not handling them correctly can lead to improper connections, as well as, damage to other optical components. Here are some of the measures you should observe when installing fiber optic cables.

Create a Comprehensive Plan

Devise a detailed plan of installation. Did you know that you can eliminate up to ninety-five percent of the problems most installers encounter by simply creating this plan? Make sure that the plan includes equipment and supplies, testing data forms, fiber cable installation, installation techniques, safety issues, equipment location, and much more.

Don’t Pull Beyond the Maximum Load Rating

Don’t pull on the fiber itself. Remember, fiber optic cables utilize fiberglass rods as their strength member. And you should only pull on the strength members, not the fiber cable itself.

It’s also important to apply proper lubricants on the long runs. You also need to make sure that they’re fully compatible with the cable jacket. For really long runs, you may want to consider using an automated puller to pull them from the middle out to the ends. While doing this, observe the cable’s allowed maximum rating.

Check the Cable Bend Radius

Although fiber is stronger than steel, it tends to break more easily when bent beyond its elastic limit. And this can severely harm the fibers. So, it’s always better to roll the Active Optic Cable (AOC) cable off the spool rather than spinning it off the spool end. Don’t twist the fiber cable; otherwise, you’ll end up stressing the fibers too. Always ensure that the cable is long enough for the run. While indoor cables can be installed directly, you may consider placing them inside the inner-duct. This provides an easier way of identification and allows you to safeguard the fiber cable against damage.

Pushing the cables can cause significant effects on the bend radius. You also want to make sure that you monitor the supply reel. This will go a long way in preventing the violation of the minimum bend radius.

Maintain Proper Communication

When installing long runs, be sure to communicate and monitor the process. Remember, fiber cables can jump off from unmonitored pulleys. There should be someone monitoring the pulling equipment and one monitoring the supply reel. It’s also important to ensure that there’s someone in charge of coordinating all people involved in the installation process.

Choose the Right Equipment

Don’t use a vehicle to pull the cable. Choosing a technique that perfectly suits the cable design, as well as, the location of installation. For instance, you may want to consider pulling the fiber cable into a conduit. Another appropriate technique entails placing the cables in a raceway of laying it inside a cable tray.

Lubrication minimizes the pulling load, as well as, the chance of breakage. Just make sure that the lubricant you choose is compatible with the cable jacket material. Properly train and instruct installation personnel. This will significantly minimize expenses through the reduction of breakage and attenuation.

Conclusion

Handling fiber optic cables isn’t that easy. But with the above tips, you can rest assured that your fiber cables will always remain safe and secure. Don’t overlook any one of them – otherwise, you might end up damaging the cables.